Senda 100,000-grade Clean Workshop, Building a “Clean Line of Defense” for Quality

Senda 100,000-grade Clean Workshop, Building a “Clean Line of Defense” for Quality

In the field of precision manufacturing, “cleanliness” is not only the first barrier to ensuring product quality, but also an important manifestation of an enterprise’s core competitiveness. Having been deeply engaged in the industry for many years, Senda has built a 100,000-level clean workshop in accordance with strict standards. From air cleanliness to environmental stability, and from intelligent transportation to material transfer, every detail interprets the ultimate pursuit of quality, building a solid “clean line of defense” for the production process.

Senda clean workshop is constructed in strict compliance with the dual standards of GB 50073-2013 Code for Design of Clean Rooms and Related Controlled Environments and GB 50591-2010 Code for Construction and Acceptance of Clean Rooms.

●Class 5 Cleanroom Requirement (≥0.1μm airborne particles ≤100,000 per m³)

●Constant temperature (20-24°C)

●Constant humidity (50%-70%)

●The static pressure difference between adjacent areas is maintained at 5-10 Pa

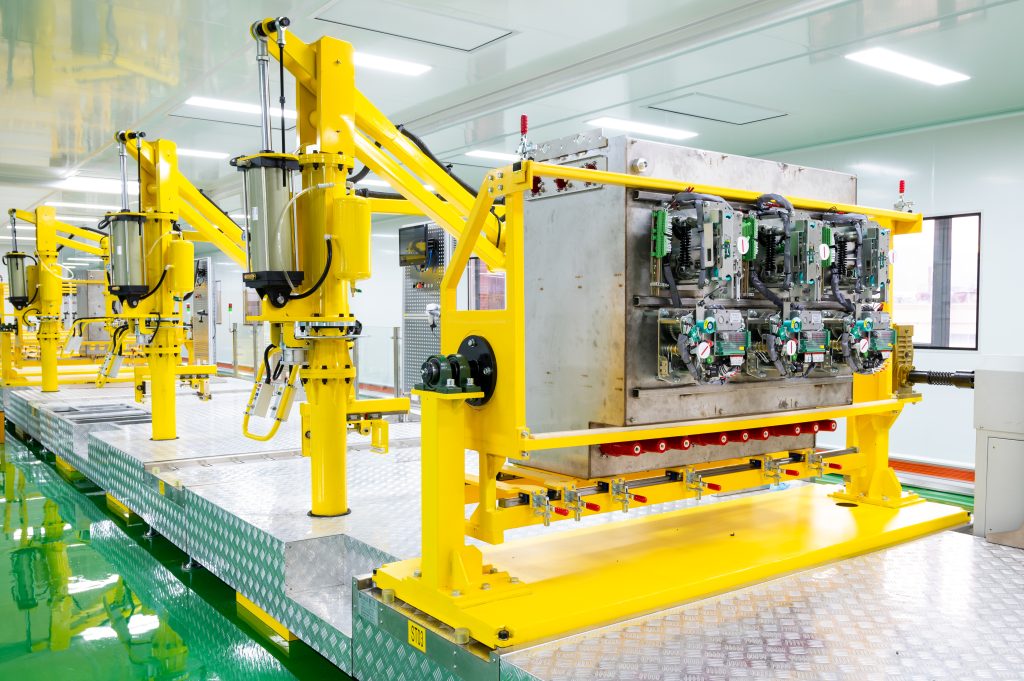

Gas box assembly line:

Configure one RGV conveyor track, using an absolute position coding system and ITS sliding contact line to meet the positioning and power supply requirements of the RGV conveyor trolley at various workstations on the production line; Equipped with an RGV conveyor car for the allocation and transportation of workstations next to the guide rail;

Material transport robot:

Using AGV automatic guidance transport vehicle for material transfer, equipped with HEPA filtration system on the body to avoid secondary pollution

Senda’s purification workshop strictly controls dust, temperature, humidity, and static electricity to prevent impurities from adhering to insulation components (such as epoxy resin insulators) inside the GIS cabinet, which can cause partial discharge or insulation breakdown, ensuring gas insulation performance and long-term reliability of equipment operation.

From strict cleanliness standards to intelligent production configurations, Senda’s 100,000-level clean workshop demonstrates its true strength through details and safeguards product quality with professional capabilities. This is not only Senda’s strict adherence to industry standards, but also a solemn commitment to customers’ trust. In the future, Senda Electric will continue to promote production optimization through technological upgrading, deepen its efforts in the field of clean production, and inject more quality-driven power into the development of the industry!

Get In Touch

Recent Posts

-

🌟Senda Electric Secures Major Bids from State Grid with Total Amount of 5.59 Million USD

Dec 16, 2025 -

Senda 100,000-grade Clean Workshop, Building a “Clean Line of Defense” for Quality

Dec 12, 2025 -

Successful Completion of Rigorous Inspection for High-Altitude RMU Project

Dec 03, 2025 -

Good News: Senda Electric Secures Significant Bid with State Grid!

Jul 14, 2025 -

What Is The Difference Between GGD Distribution Cabinet And MNS Low-Voltage Switchgear, Both Belonging To Low-Voltage Switchgear?

Jun 24, 2025

GCK-GCS-MLS低压抽出式成套开关设备.png)